Last Updated on November 26, 2025 by Emma Fajcz | Published: June 17, 2019

Whenever friends visit us in Portugal, we suggest canned fish as the perfect souvenir to take back to their family and friends. Not only is it completely delicious (way better than canned tuna at home) but it’s also wrapped in beautiful packaging—a piece of Portuguese history that is very much alive and well. But where does it come from? We visited Conserveira do Sul to find out.

Photo Credit:

Living history

“My great-grandfather founded Conserveira do Sul in 1954 and we have been working since that year, without ever closing our doors,” says Sara Costa, the director of marketing and communications for the cannery in the Algarve. “This is something that we are very proud of because Olhão had 37 factories, a very strong canning industry, which years later, in the 70s, suffered a great crisis. For the last 20 years we have been one of the few canned fish factories still working in Olhão and even in the south of Portugal.”

They didn’t only survive—they thrived.

Conserveira do Sul’s annual production is now 9 million units of canned fish and 8.3 million units of fish pastes. Most of the fish comes from the Portuguese fish auctions, particularly in Olhão, just three minutes away from the factory. But when necessary, they will import from other European countries, particularly with tuna.

In the beginning

“When we started, we were a team of more than 300 workers,” says Costa. “Nowadays we are 95. In a fishing town like Olhão, men usually worked fishing in the boats and women in the canneries. Each factory had its own personalized siren, so as soon as the fish arrived, the workers recognized the siren of their factory and left their houses, whatever time it was, 3 or 4 a.m. if necessary.

“We also had our own boats, ensuring regular fish supplies to our factory. It has always been my great-grandfather’s concern not to work for only six months, but to provide a year-round job to his workers, guaranteeing their livelihoods by not leaving them helpless and unemployed half the year.”

Inside the factory today

Now people work according to the needs of the factories and the availability of the fish, says Costa. But otherwise, the process is traditional. “Even today the fish is handled and placed in the can by hand by experienced women. This process is essential for us and allows us to guarantee high-quality canned fish. If this work was done by a machine, instead of the human hand, we would have a product with much less quality, probably with the meat of the fish mashed up.

“However, many years ago it was not only this process that was manual. Many others also were. That’s the main difference nowadays. The storage of the fish has evolved with the refrigerating chambers and many of our packaging processes are already mechanized and more evolved.

In Portugal, canned fish is an art form.

“Despite all the technical developments, the process and its stages remain similar. As soon as the fish arrives at our factory, it’s necessary to process it as soon as possible, guaranteeing its maximum freshness and quality. After canning the fish, it goes to a steam cooker with the can inverted to make sure the liquid drains, then to the addition of sauce (olive oil, tomato, mustard, whatever we wish), and later to the sealing process. This way, the product does not deteriorate because it is not in contact with the air. This natural process allows us to conserve fish in a can for four to five years. It’s perfect to consume during these years without the addition of colorants and preservatives. After this fundamental process, we finish the production with the sterilization of the cans.” – Sara Costa, Director of Marketing for Conserveira do Sul

About those labels

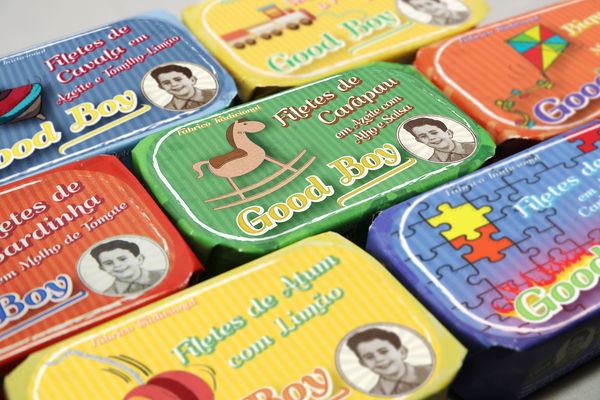

“After this process, it is only necessary to give an image and brand to our can,” says Costa. “Our Good Boy and Jupiter brands are wrapped by hand as is tradition in the Portuguese canning industry.

“Being a family business, we have a brand that means a lot to my family. In 1950, when my great-grandfather had a company dedicated to the conservation of fish in salt, he created the Good Boy brand.”

It was meant only for export, and that’s why its name is in English. He choose as the “face” of the brand his youngest son, who was then seven years old, the boy Jorge Ferreira.

“For me, it is a brand full of charisma and also shows the humor that my great-grandfather had,” says Costa. “Plus, the Good Boy’s son, my cousin Jorge Ferreira (now our sales manager), says that his father was a very naughty boy.

“I think it’s very important to have this spirit in business, not making the products too serious and boring. Therefore, it was a great challenge for us to recover 65 years later this brand that was off the market for many years and had never been marketed in Portugal. For me personally, it was an honor to be able to re-create this new image of Good Boy.”

We’re pretty big on our canned fish here in Portugal, and we’d love to share some of our favorite conservas with you. Join us on our Tastes & Traditions of Lisbon Tour, where you’ll taste for yourself just how fabulous tinned seafood can be—you’ll never look at a can of sardines the same way again!

I would like to have a job.

Hi Gurpreet, you can see all of our available job openings here: https://devourtours.com/job-opportunities/ Good luck!